Tare da saurin ci gaban masana'antar petrochemical, an yi amfani da kayan bakin karfe da yawa, wanda kuma ya gabatar da manyan buƙatu don walda na bututu da faranti.Hanyar walda bakaken bakin karfe da ta gabata an kawar da hankali a hankali, kuma ana amfani da walda ta argon don walda ta farko.

Argon arc waldi na share fage ya fi tsafta da sauri fiye da waldawar baka.A lokaci guda kuma, akwai wasu matsaloli.

A lokacin aikin walda, tun da baya na bakin karfe argon arc waldi tushe yana da sauƙin oxidized kuma yana haifar da lahani, dole ne a ɗauki matakan kariya na baya don tabbatar da kaddarorin inji da juriya na lalata walda.Don haka, dole ne a ɗauki ingantaccen kariya lokacin walda bakin karfe.

A yau muna gabatar da hanyoyin kariya da bakin karfe da aka saba amfani da su:

01

Hanyar Kariyar Argon Baya

Ana iya raba iskar kariyar da aka saba amfani da ita zuwa kariyar iskar argon mai sauki da kariyar gauran gas.Wani kaso na argon-nitrogen gauraye gas ya fi dacewa da austenitic bakin karfe waldi.Wasu iskar gas ba a amfani da su saboda tsadar su.

Kariyar hanyar cikawar Argon hanya ce ta kariyar baya ta gargajiya, wacce ke da halaye mafi kyawun kariya ta baya, mai sauƙin sarrafawa, tsafta mai girma, da ƙimar wucewa.An raba shi zuwa hanyar kariya ta kariya ta hanyar cikawar argon, hanyar kariyar cikawar argon na gida, cikawar haɗin gwiwar walda kai tsaye, hanyar kariyar walda ta argon, da sauransu.

1. murfin kariya da aka cika da hanyar kariya ta argon

Ana amfani da wannan hanya sau da yawa wajen walda bakin karfe na faranti da manyan bututun diamita.An haɗa murfin kariyar zuwa bututun ƙarfe da bututun iskar gas na argon.Ana buɗe bawul ɗin gas ɗin argon don cika murfin kariya tare da iskar argon.

Ana buƙatar wani mutum ya riƙe bututun ƙarfe a matsayin abin hannu domin murfin kariya ya zame akan narkakken tafkin da ke bayansa don aiki tare da walda na waje na farantin ko bututu.

Ta wannan hanyar, gefen baya yana da kariya sosai, kuma kariya ta mayar da hankali.Gas ɗin argon baya buƙatar buɗewa da yawa, kuma iskar argon ɗin yana raguwa kaɗan.

2. Kariyar cikawar argon na gida

Yana da sauƙi a yi amfani da kariyar gida don bututun mai tare da ƙaramin sarari na gida da guntun girma.

Hanyar: Rufe haɗin walda na bututu da tef (don hana zubar iska).Rufe duka ƙarshen bututu tare da soso, roba, harsashi na takarda, da sauransu. Saka igiyar argon daga ƙarshen ɗaya kuma cika shi da argon.Sauran ƙarshen bututu ya fi kyau a rufe.Haɗa ƙaramin rami (babu buƙatar soso), wanda zai sauƙaƙe haɗin haɗin walda na ƙarshe kuma ba zai haifar da ɓarna ba saboda matsanancin matsin lamba na ciki.

A lokacin walda, don hana fitar da iskar argon mai yawa daga cikin kabu na walda, yakamata a yayyage tef ɗin da ke rufe walda a cikin sassan, wanda zai iya rage ƙarin asarar argon gas da kuma kare kariya mai kyau.An ɓata fasali, cajin argon yana jinkirin, farashi ya yi yawa, da dai sauransu.

3 .Direct argon cika hanyar kariya ga haɗin gwiwar walda

Don bututun da ke da tsayi da yawa kuma suna da ƙananan diamita, cikawar argon na gida yana da ɓatacce, ba za a iya tabbatar da ingancin ba, kuma farashin aikin ya yi yawa.Don adana farashi, ana iya amfani da hanyar cikawar argon kai tsaye a haɗin haɗin gwiwa.

Hanyar yin matosai a bangarorin biyu na kabu na weld

Sanya soso a cikin filogi tare da diamita mafi girma don bututu kuma haɗa guda biyu na soso tare da waya a nesa na 300-400mm don samar da filogi biyu.An haɗa ƙarshen filogi ɗaya zuwa guntun karfe mai tsayi.

Lokacin daidaitawa, sanya matosai a 150-200mm a bangarorin biyu na walda don waldawa.Dogon ƙarfen waya a ƙarshen ɗaya yakamata ya fi tsayin bututun a ƙarshen walda kuma ya fallasa ƙarshen bututu.Ɗayan ƙarshen ƙananan ƙananan bututun ƙarfe ya kamata a daidaita shi kuma ɗayan ƙarshen ya kamata a haɗa shi da igiyar argon.Saka ƙarshen da aka kwance a cikin madaidaicin weld kuma cika shi da argon.Mafi kyawun hanyar shigar da ita ita ce mafi girman ɓangaren, ta yadda kafin haɗin gwiwa na ƙarshe na walda na ƙasa, za a iya fitar da ƙaramin bututun da sauran iskar gas a cikin bututun.Bayan walda, yi amfani da waya don cire filogi.

Hanyar kariyar takarda mai narkewa

Kafin taro, liƙa takarda mai narkewa da ruwa a 150-200mm a bangarorin biyu na haɗin gwiwar walda a matsayin hatimi.Bayan daidaitawa, yi amfani da hanyar walda mai kumburi iri ɗaya kamar filogin soso.Lokacin da aka gwada bututun don matsa lamba na hydraulic, takarda mai narkewar ruwa za ta narke kuma a fitar da shi da ruwa.

4. Argon gas kariya hukunci

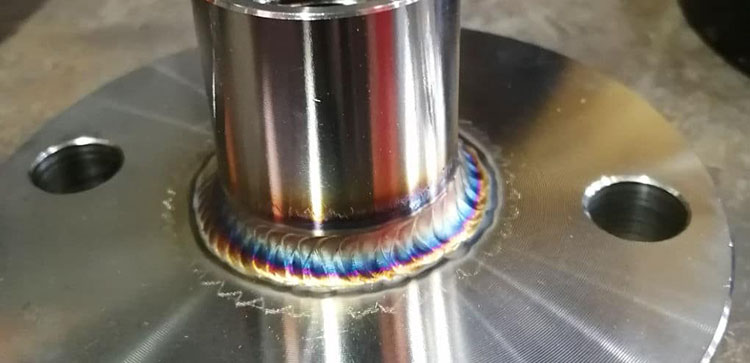

Ana iya yin la'akari da tasirin kariya na gas na argon bisa ga launi na walda na ciki, don haka mai aiki zai iya daidaita gas ɗin argon bisa ga launi don cimma sakamako mafi kyau na kariya.Launuka fari ne da zinariya, kuma launin toka da baki sune mafi muni.

5. Kariya don Kariyar Bakin Karfe

(1) Kafin waldawar argon, bayan walda ya kamata a kiyaye shi ta hanyar cika shi da argon a gaba.Yawan kwarara ya kamata ya fi girma.Bayan fitar da iskar, yawan kwarara zai ragu a hankali.A lokacin aikin waldawa, ya kamata a cika bututu da argon ci gaba.Za a iya cire bututun argon ne kawai bayan an gama walda don walda ɗin ya sami kariya sosai.

Bugu da ƙari, ya kamata a ba da hankali na musamman ga gaskiyar cewa za'a iya yin walda kawai bayan iska ta ƙare, in ba haka ba za a shafi tasirin kariya na cikawar argon.

(2) Yawan iskar gas na argon ya kamata ya dace.Idan yawan kwarara ya yi ƙanƙara, kariyar ba ta da kyau, kuma bayan walda yana da sauƙi oxidized;idan magudanar ruwa ya yi girma da yawa, za a haifar da lahani irin su rashin ƙarfi na tushen walda, wanda zai shafi ingancin walda.

(3) Ya kamata a sanya mashigin iskar gas na argon a matsayin ƙasa mai yiwuwa a cikin rufaffiyar sashin, kuma ya kamata a sanya ramin fitar da iska dan kadan a cikin sashin rufaffiyar bututu.Saboda argon ya fi nauyi fiye da iska, cika argon daga matsayi mafi ƙasƙanci zai iya tabbatar da mafi girma, kuma tasirin kariya na cikawar argon zai fi kyau.

(4) Don rage asarar iskar argon a cikin bututu daga rata tsakanin haɗin gwiwa, wanda ke shafar tasirin kariya kuma yana ƙara yawan farashi, ana iya sanya tef tare da rata tsakanin haɗin walda kafin waldawa, barin kawai tsayi. ga wani ci gaba da walda ta walda, da kuma cire tef yayin walda.

02

Hanyar kariyar walda mai kariyar kai

Wayar walda mai kariyar kai a baya ita ce wayar walda tare da sutura.A lokacin walda, murfin sa na kariya zai shiga cikin cikakkiyar kariya ta gaba da bayan tafkin narkakkar, samar da wani katafaren kariya mai yawa don hana bayan ƙullin walda daga zama oxidized.Wannan kariyar kariyar za ta fado ta atomatik bayan sanyaya, kuma za a goge shi kuma a gwada shi yayin gwajin matsa lamba.za a share.

Hanyar amfani da irin wannan irin waldi waya ne m guda da na talakawa argon baka waldi m core waya, da kuma yi na weld karfe iya saduwa da bukatun.

Wayar walda mai kariyar kai ba ta iyakance ta yanayi daban-daban na walda, yin shirye-shiryen walda cikin sauri da sauƙi.Duk da haka, saboda rufin da ke saman wayar walda, za a sami rashin jin daɗi lokacin da ma'aikatan walda suka yi aiki da shi.

Saboda rashin jituwa da dabarun walda waɗanda ba su dace da wayoyi masu rufaffiyar walda ba, lahani irin su concavities wani lokaci suna faruwa.Don haka, akwai wasu buƙatu don ƙwarewar aiki da dabarun ma'aikatan walda.Wayar garkuwar kai ita ce mafi kyawun amfani da na'urori masu mahimmanci saboda tsadar sa.

Bugu da kari, akwai nau'ikan wayoyi na walda masu garkuwa da kansu da yawa a kasuwa da za a zaba daga ciki, kuma amfaninsu ma ya bambanta.

Lokacin aikawa: Satumba-21-2023