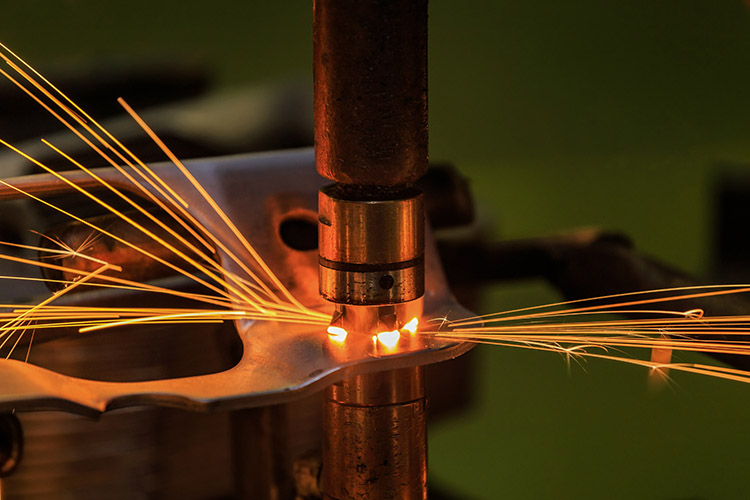

Spot walda hanya ce ta juriya ta walƙiya inda ake haɗa walda a cikin haɗin gwiwar cinya kuma a matse shi tsakanin na'urorin lantarki guda biyu, kuma ƙarfen tushe yana narkar da shi ta hanyar juriya don samar da haɗin gwiwa.

Ana amfani da walda ta Spot a cikin abubuwa masu zuwa:

1. Lap hadin gwiwa na takardar stamping sassa, kamar mota taksi, karusa, kifi sikelin allo na girbi, da dai sauransu.

2. Sirin farantin karfe da sassan karfe da tsarin fata, kamar bangon gefe da rufin karusai, fale-falen ɗaki na tirela, mazugi masu girbi, da sauransu.

3. Screens, sarari Frames da giciye sanduna, da dai sauransu.

Characteristic

Lokacin waldawar tabo, waldar ɗin tana samar da haɗin gwiwa kuma ana danna tsakanin na'urori biyu.Babban halayensa sune kamar haka:

1. Lokacin dumama yankin haɗin yana da ɗan gajeren lokaci yayin waldawar tabo, kuma saurin walda yana da sauri.

2. Spot walda kawai yana cinye makamashin lantarki, kuma baya buƙatar kayan cikawa ko ruwa, gas, da sauransu.

3. The ingancin tabo waldi ne yafi garanti da tabo waldi inji.Aiki yana da sauƙi, matakin injina da sarrafa kansa yana da girma, kuma yawan aiki yana da yawa.

4. Ƙananan ƙarfin aiki da kyakkyawan yanayin aiki.

5. Tun lokacin da aka kammala aikin waldawa a cikin ɗan gajeren lokaci, ana buƙatar babban halin yanzu da matsa lamba, don haka tsarin kula da tsarin ya fi rikitarwa, injin walda yana da babban iko, kuma farashin kayan aiki yana da ɗanɗano. babba.

6.Yana da wuya a gudanar da gwaje-gwajen da ba a lalata ba a kan gidajen abinci.

Tsarin aiki

A surface na workpiece ya kamata a tsabtace kafin waldi.Hanyar tsaftacewa da aka saba amfani da ita ita ce tsaftacewa, wato, ɗora a cikin sulfuric acid mai zafi tare da maida hankali na 10%, sannan a wanke da ruwan zafi.Tsarin walda na musamman shine kamar haka:

(1) Aika da workpiece hadin gwiwa tsakanin babba da ƙananan na'urorin lantarki na tabo waldi inji da kuma matsa shi;

(2) electrification, sabõda haka, lamba saman na biyu workpieces suna mai tsanani da kuma partially narke don samar da wani nugget;

(3) Ci gaba da matsa lamba bayan an yanke wutar lantarki, don haka an sanyaya nugget kuma an ƙarfafa shi a ƙarƙashin matsin lamba don samar da haɗin gwiwa na solder;

(4) Cire matsa lamba kuma fitar da kayan aikin.

Abubuwa masu tasiri

Babban abubuwan da ke shafar ingancin walda sune walƙiyar halin yanzu da lokacin kuzari, matsa lamba na lantarki da shunt, da sauransu.

1. Welding halin yanzu da kuzari lokaci

Dangane da girman walƙiyar halin yanzu da tsawon lokacin ƙarfafawa, ana iya raba walda tabo zuwa nau'ikan biyu: ƙayyadaddun ƙayyadaddun ƙarfi da ƙayyadaddun taushi.Ƙayyadaddun ƙayyadaddun da ke wuce babban halin yanzu a cikin ɗan gajeren lokaci ana kiransa da ƙayyadaddun bayanai.Yana da abũbuwan amfãni daga high yawan aiki, dogon electrode rayuwa, da ƙananan nakasawa na walda.Ya dace da welding karafa tare da mafi ingancin thermal watsin.Ƙayyadaddun ƙayyadaddun da ke wucewa ƙarami na lokaci mai tsawo ana kiransa ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun abubuwa, wanda ke da ƙananan yawan aiki kuma ya dace da ƙarfe na walda wanda ke da wuyar taurare.

2. Electrode matsa lamba

A lokacin waldawar tabo, matsin lamba da lantarki ke yi akan walda ana kiransa matsin lamba.Ya kamata a zaɓi matsa lamba na lantarki daidai.Lokacin da matsa lamba ne high, da shrinkage porosity da shrinkage rami wanda zai iya faruwa a lokacin da nugget solidifies za a iya kawar da, amma dangane juriya da halin yanzu yawa rage, sakamakon rashin isasshen dumama na waldi da kuma raguwa a cikin diamita na nugget na nugget. solder hadin gwiwa.Ƙarfin haɗin haɗin siyar yana raguwa.Ana iya zaɓar girman matsa lamba na lantarki bisa ga dalilai masu zuwa:

(1) Kayan aikin walda.Mafi girman ƙarfin zafin jiki na kayan.Mafi girman matsa lamba na lantarki da ake buƙata.Don haka, lokacin walda bakin karfe da karfe mai jure zafi, karfin wutar lantarki ya kamata ya zama sama da na karamin karfen carbon.

(2) Alamar walda.Da tsananin ƙayyadaddun walda, mafi girman matsin lamba.

3. shuru

Lokacin waldawar tabo, ana kiran abin da ke gudana daga wajen babban da'irar walda ta shunt.Shunt yana rage halin yanzu da ke gudana ta yankin waldawa, yana haifar da rashin isasshen dumama, yana haifar da raguwa mai yawa a cikin ƙarfin haɗin gwiwa na solder kuma yana shafar ingancin walda.Abubuwan da suka shafi matakin karkatar da su sun haɗa da abubuwa masu zuwa:

(1) Kauri daga cikin walda da tazarar na solder gidajen abinci.Yayin da nisa tsakanin kayan haɗin gwal yana ƙaruwa, juriya na shunt yana ƙaruwa kuma matakin shunt yana raguwa.Lokacin da aka karɓi farar digo na al'ada na 30-50mm, shunt halin yanzu yana lissafin 25% -40% na jimlar halin yanzu, kuma yayin da kauri na walda ya ragu, matakin shunt shima yana raguwa.

(2) Yanayin yanayin walda.Lokacin da oxides ko datti a saman walda, juriya na hulɗar tsakanin walda biyu yana ƙaruwa, kuma halin yanzu ta wurin waldawa yana raguwa, wato, matakin shunt yana ƙaruwa.A workpiece za a iya pickled, sandblasted ko goge.

Kariyar Tsaro

(1) Canjin ƙafa na injin walda yakamata ya kasance yana da ingantaccen murfin kariya don hana kunnawa cikin haɗari.

(2) Wurin aiki za a sanye shi da baffa don hana bazuwar tartsatsin aiki.

(3) Masu walda su sanya gilashin kariya masu lebur lokacin walda.

(4) Wurin da aka sanya na'urar walda a bushe, kuma a rufe ƙasa da allunan hana ƙetare.

(5) Bayan aikin walda, yakamata a yanke wutar lantarki, sannan a tsawaita ruwan sanyi na tsawon daƙiƙa 10 kafin rufewa.Lokacin da zafin jiki ya yi ƙasa, ya kamata a cire ruwan da aka tara a cikin hanyar ruwa don hana daskarewa.

Lokacin aikawa: Yuli-31-2023