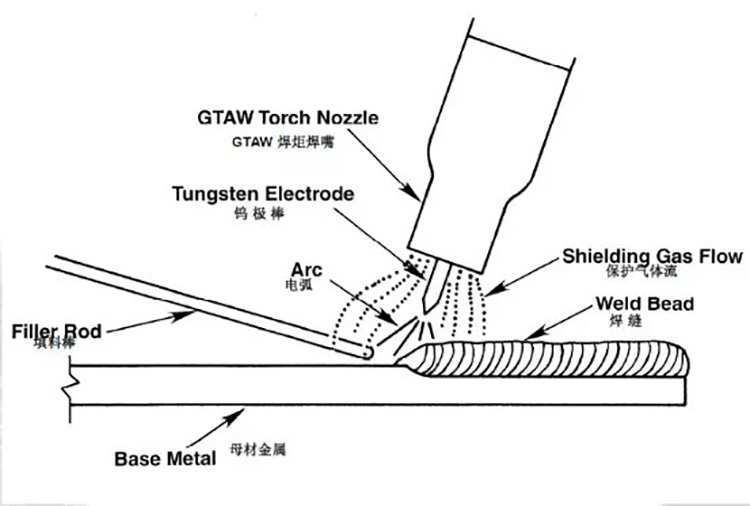

Argon tungsten arc walda yana amfani da argon a matsayin iskar kariya don zafi da narkar da kayan walda da kanta (shima yana narke lokacin da aka ƙara ƙarfe mai filler) ta hanyar baka da aka samar tsakanin wutar lantarki ta tungsten da jikin walda, sannan ta samar da walda. na Weld karfe Way.Thetungsten electrode,Weld pool, arc da haɗin gwiwa yankin kabu mai zafi da baka suna da kariya daga gurɓataccen yanayi ta hanyar kwararar argon.

A lokacin waldi na argon baka, matsayin dangi na tocilan, ƙarfe mai filler da walƙiya ana nuna su a cikin adadi da ke ƙasa: tsayin baka gabaɗaya 1 ~ 1.5 sau diamita na lantarki tungsten.Lokacin da aka dakatar da walda, ana fara fitar da karfen filler daga cikin ruwan narkakkar (ana ƙara ƙarfen filler gwargwadon kauri na walda), kuma ƙarshen zafi yana buƙatar zama ƙarƙashin kariya daga kwararar argon don hana iskar oxygen. .

1. Wutar walda (Torch)

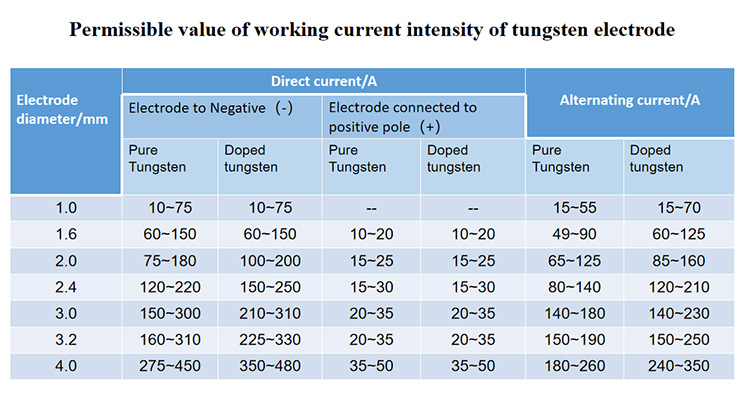

Bugu da ƙari, danne lantarki na tungsten da kuma isar da wutar lantarki, argon tungsten arc welding torch (wanda aka fi sani da walda torch) yana buƙatar fesa iskar kariya.Manyan bindigogin walda na zamani suna buƙatar amfani da bindigogin walda masu sanyaya ruwa don yin walda na dogon lokaci.Saboda haka, daidai amfani da kariya na walda tocilan yana da matukar muhimmanci.Tungsten electrode load current (A) ana nuna shi a cikin tebur da ke ƙasa.

2. Hanyar gas

Hanyar iskar gas ta ƙunshi matsi na argon cylinder rage bawul, mita kwarara, tiyo da bawul ɗin iskar gas na lantarki (cikin injin walda).Ana amfani da bawul ɗin rage matsa lamba don rage matsa lamba da daidaita matsa lamba na iskar gas mai karewa.Ana amfani da ma'aunin motsi don daidaitawa da daidaita kwararar iskar garkuwa.Injunan waldawa na Argon galibi suna amfani da na'ura mai juzu'i mai haɗawa, wanda ya dace kuma abin dogaro don amfani.

Lokacin waldawar argon, abin da ake buƙata don tsabtar iskar argon shine cewa bakin karfe na chromium-nickel yakamata ya zama ≥99.7%, kuma ƙarfe mai ƙarfi ya zama ≥99.98%.

(1) Argon iskar gas ce, kuma ba shi da sauƙin amsawa da sauran kayan ƙarfe da iskar gas.Bugu da ƙari, saboda sakamakon kwantar da hankali na iska, yankin da ke fama da zafi na weld yana da ƙananan ƙananan kuma lalacewar walƙiya yana da ƙananan.Shi ne mafi manufa garkuwa garkuwa ga argon tungsten baka waldi.

(2) An fi amfani da Argon don kare narkakkar tafkin yadda ya kamata, da hana iska daga lalatawar tafkin da kuma haifar da oxidation a lokacin aikin walda, kuma a lokaci guda yadda ya kamata ya keɓe iska a cikin yankin walda, ta yadda yankin walda ya kasance. kariya kuma an inganta aikin walda.

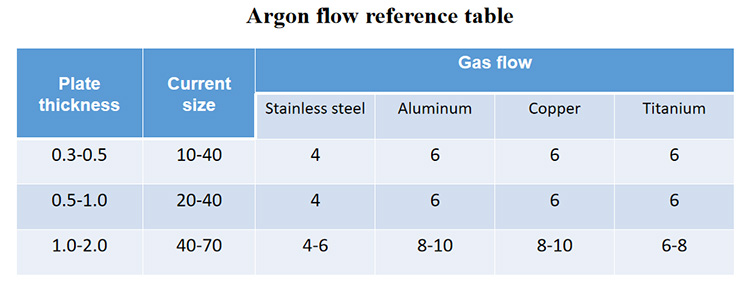

(3) Hanyar gyare-gyare an ƙaddara bisa ga kayan ƙarfe da za a yi amfani da su, girman girman halin yanzu, da hanyar waldawa: mafi girma na yanzu, mafi girma gas mai kariya.Don kayan abubuwa masu aiki, yakamata a ƙarfafa iskar kariya don ƙara yawan kwarara.

3. Ƙayyadaddun sigogi

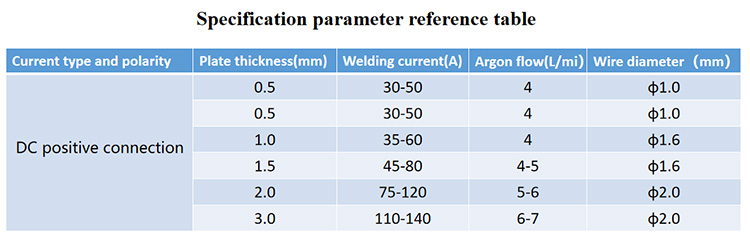

Ma'auni na walda na argon tungsten baka sun fi haɗa da halin yanzu, ƙarfin lantarki, saurin walda, da kwararar iskar gas na argon, kuma ƙimar su tana da alaƙa da nau'in kayan da za a yi walda, kaurin faranti da nau'in haɗin gwiwa.

Sauran sigogi kamar tsayin tungsten electrode da ke fitowa daga bututun ƙarfe gabaɗaya sau 1-2 a diamita na tungsten electrode, nisa tsakanin tungsten lantarki da walda (tsawon baka) gabaɗaya sau 1.5 diamita na tungsten. Electrode, kuma girman bututun ƙarfe an ƙaddara bayan an ƙaddara ƙimar halin yanzu.Zaɓi sake.

General bakin karfe argon baka waldi bayani dalla-dalla ne kamar haka:

4. Tsaftace kafin walda

Tungsten argon arc waldi yana da matukar damuwa ga gurbatar walda da filler karfe surface, don haka man shafawa, shafi, mai mai da kuma oxide fim a kan surface na waldi dole ne a cire kafin waldi.

5. Fasahar aminci

Masu aikin waldawar baka na argon tungsten dole ne su sanya abin rufe fuska, safar hannu, tufafin aiki, da takalman aiki don guje wa ƙona ultraviolet da infrared a cikin baka.Na'urorin walda na Steyr tungsten argon an sanye su da manyan na'urorin arc masu yawan gaske.Ko da yake ƙananan wutar lantarki mai ƙarfi mai ƙarfi mai ƙarfi ba zai girgiza mai aiki ba, lokacin da aikin rufewa ya yi rauni, wutar lantarki mai ƙarfi zai ƙone fatar hannun mai aiki, kuma yana da wahala a warkewa, don haka aikin insulation. na hannun walda dole ne a duba akai-akai.A lokacin waldawar argon tungsten, ya kamata a inganta samun iska a wurin walda.

Lura: Babban abu shine ƙwararru da ƙwazo.Kaurin allo, lokacin dannawa, da na yanzu duk suna da alaƙa, kuma suna buƙatar haɗin kai da juna.

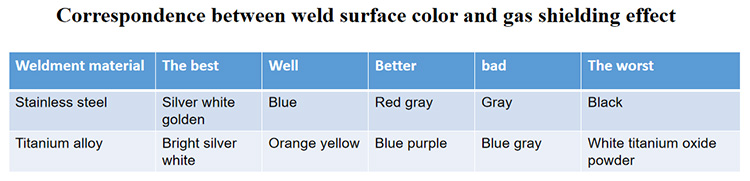

Lokacin walda, kar a nuna wurin allura a wurin walda a farkon, sannan a buge shi babu komai a farko don fitar da iskar da ke cikin bututu, don kada waldar ta tashi kuma ba a sami baƙar fata ba.Bayan 'yan seconds, ta wannan hanya, bakin karfe yana kiyaye shi ta hanyar iskar argon a lokacin sanyaya, don haka ba zai zama baƙar fata ba, har ma da ruwan wankewa da takardar gogewa suna ajiyewa.Ana iya amfani da wannan kawai don waldawar tabo.Idan ka ja waldi na dogon lokaci, babu wata hanya.Tabbas allon zai canza launi.Dole ne ku jira gogewa da tsaftacewa.

Lokacin aikawa: Mayu-16-2023