Garkuwar Karfe Arc Welding (wanda aka gajarta da SMAW).Ka'idar ita ce: an samar da baka tsakanin rufaffen lantarki da karfen tushe, da kuma hanyar walda ta amfani da zafin baka don narkar da lantarki da karfen tushe.Wurin waje na lantarki an rufe shi da walda kuma yana narkewa lokacin da aka fallasa shi zuwa zafi, wanda ke da ayyuka na daidaita baka, samar da slag, deoxidizing, da tacewa.Saboda yana buƙatar kayan aiki mai sauƙi da aiki mai sassauƙa, ana iya sauƙaƙe shi cikin sauƙi zuwa walda waɗanda aka kafa ta wurare daban-daban da haɗin gwiwa daban-daban a sararin samaniya.Saboda haka, har yanzu ana amfani da shi sosai a halin yanzu.

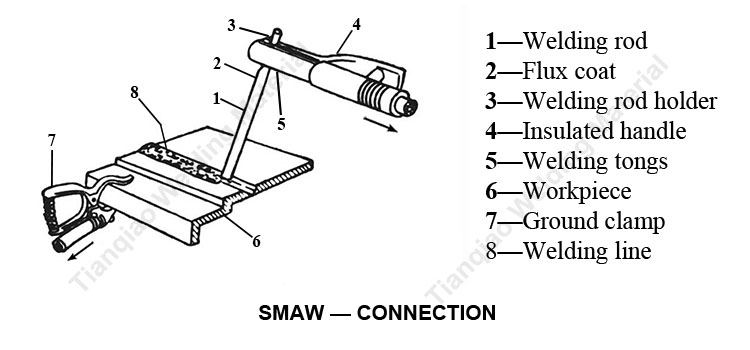

Hoto 1: Garkuwar Karfe Arc Haɗin Welding

Ana nuna walda ta hannun hannu a cikin adadi:

Kafin waldawa, haɗa kayan aikin walda da kayan walda zuwa sanduna biyu na na'urar waldawa ta lantarki da matse sandar walda tare da kayan walda.A lokacin waldi, sandar walda da kayan aiki suna cikin lamba nan take, suna yin gajeriyar kewayawa, sannan an raba su da wani tazara (kimanin 2-4mm), kuma ana kunna baka.

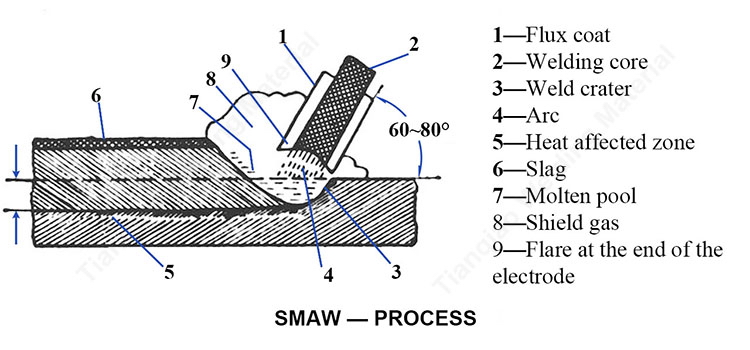

Hoto 2: Garkuwar Karfe Arc-Tsarin Welding

Kayan aikin da ke ƙarƙashin baka nan da nan ya narke don samar da narkakkar ruwa na Semi-oval.Bayan an narkar da murfin lantarki, wani sashi nasa ya zama iskar gas da ke kewaye da baka don ware shi daga iska, ta haka ne ke kare karfen ruwa daga iskar oxygen da nitrogen;Wani sashe nasa ya zama narkakkar tuffa, ko a fesa shi a cikin tafkin narkakkar shi kadai, ko kuma ya narke da tsakiya Ana fesa narkakkar digon karfen ruwa zuwa tafkin narkakkar tare.

A cikin baka da narkakken tafkin, ƙarfen ruwa, slag da iskar gas za su fuskanci wasu canje-canje na zahiri da na sinadarai tare da juna, kamar narkar da iskar gas a cikin ƙarfen ruwa da haɓakar oxidation-reduction reaction.Gas da tukwane a cikin narkakken tafkin suna ta iyo sama saboda nauyi mai nauyi.Lokacin da aka cire baka, zafin jiki yana raguwa kuma ƙarfe da slag za su ƙarfafa ɗaya bayan ɗaya.Ta wannan hanyar, ƙarfe biyu na ƙarfe suna haɗuwa da narke da ƙarfe na walda.Domin kuwa raguwar tulun ya sha bamban da na karfe, sai ya zame a kan harsashin karfe da kuma iyakar karfe, kuma harsashin na iya fadowa kai tsaye, ko kuma ya fado bayan an buga shi, sai kuma karfen weld din tare da sikelin kifi. za a iya fallasa.

Babban kayan aikin walda na hannu shine na'urar waldawa ta lantarki.Na'ura mai waldawa lantarki shine tushen wutar lantarki wanda ke samar da baka mai walda, kuma akwai nau'ikan AC da DC iri biyu.A halin yanzu, akwai nau'ikan nau'ikan walda na lantarki da ake samarwa a kasar Sin, wadanda za a iya raba su zuwa na'urorin walda na AC da na'urorin walda wutar lantarki na DC bisa tsarinsu.

Akwai hanyoyin haɗi daban-daban guda biyu don injin walda na DC.Lokacin da aka haɗa na'urar zuwa wutar lantarki mara kyau kuma an haɗa kayan aiki zuwa na'urar lantarki mai kyau, ita ce hanyar haɗi mai kyau;akasin haka shine hanyar haɗin kai.Gabaɗaya, lokacin waldawa tare da electrode low-hydrogen alkaline (kamarE7018, E7016), don sanya baka ya ƙone a tsaye, an ƙulla amfani da hanyar haɗin baya na DC;lokacin amfani da electrode acid (kamarE6013, J422) don walda faranti na karfe mai kauri, ana amfani da hanyar haɗin gaba, saboda ɓangaren anode Yanayin zafin jiki ya fi girma fiye da ɓangaren cathode, kuma hanyar haɗin kai na iya samun zurfin shigar ciki;a lokacin walda bakin bakin karfe faranti da kuma maras taferrous karafa, da baya dangane da hanyar da ake amfani.Lokacin waldawa tare da alternating current, tun da polarity yana canzawa a madadin, babu buƙatar zaɓar haɗin polarity.

Kayan walda don waldawa da hannu, sandar walda ce ta lantarki, wacce ta ƙunshi ginshiƙin ƙarfe da abin rufe fuska a waje na asalin ƙarfe (Duba kuma duba.A abun da ke ciki na walda lantarki).

Walda core

Matsayin karfen core (welding core) shine yafi gudanar da wutar lantarki da samar da wani karfe da aka ajiye tare da wani abun da ke ciki a karshen wutar lantarki.Ana iya yin ginshiƙin walda da ƙarfe daban-daban.Abun da ke ciki na core waldi kai tsaye rinjayar da abun da ke ciki da kuma yi na ajiyan karfe.Don haka, ana buƙatar ainihin walƙiya don rage abun ciki na abubuwa masu cutarwa.Baya ga iyakance S da P, wasu sandunan walda sun buƙaci cibiyar walda don sarrafa As, Sb, Sn da sauran abubuwa.

Hoto 3: Tianqiao welding electrode E6013

Tufafin Flux

Ana iya kiran murfin Electrode kuma ana iya kiran fenti.Babban manufar rufe shi a kan ainihin shine don sauƙaƙe aikin walda da kuma tabbatar da cewa karfen da aka ajiye yana da wani tsari da aiki.Za a iya haɗe rufin lantarki tare da ɗaruruwan foda na ɗanyen abu kamar oxides, carbonates, silicates, organics, fluorides, ferroalloys da samfuran sinadarai bisa ga ƙayyadaddun tsari.Za a iya raba albarkatun kasa iri-iri zuwa nau'ikan masu zuwa gwargwadon rawar da suke takawa a cikin rufin lantarki:

1. Stabilizer yana sa wutar lantarki mai sauƙi don fara baka kuma zai iya ci gaba da ci gaba da ƙonewa a lokacin aikin walda.Duk wani abu mai sauƙin ionize zai iya daidaita baka.Gabaɗaya, ana amfani da mahadi na alkali karafa da alkaline ƙasa karafa, kamar potassium carbonate, sodium carbonate, marmara, da dai sauransu.

2. Mai samar da Slag zai iya samar da narkakkar tudu tare da wasu kaddarorin jiki da sinadarai yayin walda, rufe saman narkakkar karfen, kare wurin walda da inganta siffar walda.

3. Deoxidizer ta hanyar maganin sinadarai na ƙarfe a cikin tsarin waldawa don rage abun ciki na oxygen a cikin nau'in weld kuma inganta kayan aikin injiniya na weld.Babban abubuwan deoxidizers sune ferromanganese, ferrosilicon, da ferro-titanium.

4. Mai samar da iskar gas zai iya rabawa da kuma 'yantar da iskar gas a ƙarƙashin aikin arc high zafin jiki don kare baka da narkakken tafkin da kuma hana kutsewar iskar oxygen da nitrogen a cikin iska mai kewaye.

5. Alloying Agent Ana amfani da shi don ramawa don ƙona abubuwan gami da sauye-sauyen abubuwan gami zuwa walda yayin aikin walda don tabbatar da cewa ƙarfe na walda ya sami ingantaccen tsarin sinadarai da aiki.

6. Plasticizing Lubricant Ƙara filastik, zamewa da ruwa na foda mai rufi a cikin tsarin latsawa na walda don inganta ingancin latsawa na sandar walda kuma rage eccentricity.

7. Adhesives Yi shafi foda da wani danko a lokacin matsa shafi tsari, iya da tabbaci bond tare da waldi core, da kuma yin waldi sanda shafi da wani ƙarfi bayan bushewa.

Lokacin aikawa: Yuli-27-2021