Damuwar walda tana faruwa ne sakamakon rashin daidaituwar zafin jiki na rarraba walda wanda ke haifar da walƙiya, haɓakar zafin jiki da ƙaddamar da ƙarfe na walda, da sauransu, don haka aikin walda ba makawa zai haifar da damuwa.

Hanyar da ta fi dacewa don kawar da damuwa na saura shine yanayin zafi mai zafi, wato, dumama weldment zuwa wani zafin jiki da kuma riƙe shi na wani lokaci a cikin tanderun maganin zafi, da kuma amfani da rage yawan amfanin ƙasa na kayan. a babban zafin jiki don haifar da kwararar filastik a wuraren da babban damuwa na ciki.Nakasar roba a hankali tana raguwa, kuma lalatawar filastik a hankali yana ƙaruwa don rage damuwa.

1.Zaɓin hanyar maganin zafi

Tasirin jiyya na zafi bayan walda akan ƙarfin juzu'i da ƙayyadaddun ƙaƙƙarfan ƙarfe yana da alaƙa da zafin zafin zafi da riƙe lokaci.Tasirin maganin zafi bayan walda akan tasirin taurin ƙarfe na weld ya bambanta da nau'ikan ƙarfe daban-daban.

Maganin zafi bayan walda gabaɗaya yana ɗaukar zafin zafin jiki guda ɗaya ko daidaitawa tare da yanayin zafi mai zafi.Don haɗin haɗin gas ɗin walda, ana ɗaukar daidaitawa da yanayin zafi mai girma.Wannan shi ne saboda hatsi na kabu na walda gas da kuma yankin da zafi ya shafa suna da yawa, kuma hatsi suna buƙatar tsaftacewa, don haka ana amfani da magani na yau da kullum.

Duk da haka, daidaitawa guda ɗaya ba zai iya kawar da damuwa na saura ba, don haka ana buƙatar matsanancin zafin jiki don kawar da damuwa.A guda matsakaici-zazzabi tempering ne kawai dace da taro da waldi na manyan talakawa low-carbon karfe kwantena harhada a kan site, da kuma manufar shi ne a cimma partially kawar da saura danniya da dehydrogenation.

A mafi yawan lokuta, ana amfani da zafin zafin jiki guda ɗaya.Dumama da sanyi na maganin zafi bai kamata ya zama da sauri ba, kuma bangon ciki da na waje ya kamata ya zama daidai.

2.Hanyoyin maganin zafi da ake amfani da su a cikin tasoshin matsa lamba

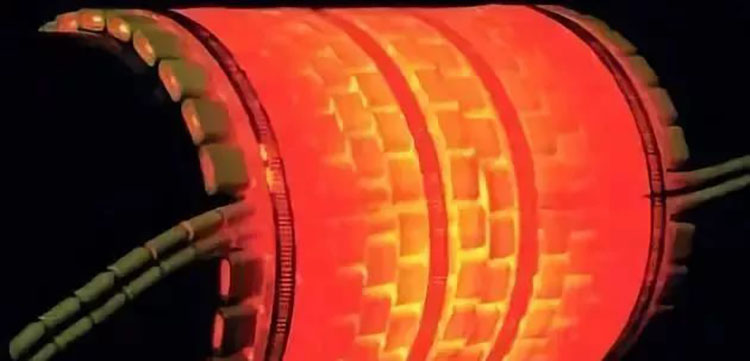

Akwai nau'i biyu na hanyoyin maganin zafi don tasoshin matsa lamba: daya shine maganin zafi don inganta kayan aikin injiniya;ɗayan kuma shine maganin zafi bayan walda (PWHT).Yadu magana, post-weld zafi magani ne zafi magani na welded yankin ko welded aka gyara bayan workpiece ne welded.

Abubuwan da ke cikin ƙayyadaddun sun haɗa da kwantar da hankali na danniya, cikakken ɓarna, ingantaccen bayani, daidaitawa, daidaitawa tare da fushi, fushi, ƙarancin zafin jiki na damuwa, maganin zafi mai zafi, da dai sauransu.

A cikin kunkuntar ma'ana, bayan-weld zafi magani kawai yana nufin damuwa taimako annealing, wato, don inganta aikin na walda zone da kuma kawar da cutarwa illa kamar waldi saura damuwa, ta yadda daidai da kuma cikakken zafi da walda yankin. da sassa masu alaƙa da ke ƙasa da canjin lokaci na ƙarfe 2 yanayin zafin jiki, sannan aiwatar da sanyaya uniform.A yawancin lokuta maganin zafi na bayan walda da aka tattauna shine ainihin maganin jinyar damuwa da zafi.

3.Manufar maganin zafi bayan walda

(1).Shakata da damuwa saura walda.

(2).Tabbatar da siffar da girman tsarin kuma rage murdiya.

(3).Haɓaka aikin ƙarfe na tushe da haɗin gwiwar welded, gami da:

a.Inganta filastik na ƙarfe na walda.

b.Rage taurin yankin da zafi ya shafa.

c.Inganta taurin karaya.

d.Inganta ƙarfin gajiya.

e.Mayar ko ƙara ƙarfin yawan amfanin ƙasa da aka rage a cikin sanyi.

(4).Inganta ikon yin tsayayya da lalata damuwa.

(5).Ci gaba da fitar da iskar gas mai cutarwa a cikin ƙarfen walda, musamman hydrogen, don hana faruwar tsagewar tsagewa.

4.Hukuncin wajibcin PWHT

Ko da bayan-weld zafi magani wajibi ne ga matsa lamba jirgin ruwa ya kamata a fili a kayyade a cikin zane, wanda ake bukata da halin yanzu matsa lamba zane code.

Domin welded matsa lamba tasoshin, akwai babban saura danniya a cikin walda zone, da kuma illar da saura danniya.An bayyana kawai a ƙarƙashin wasu sharuɗɗa.Lokacin da ragowar damuwa ya haɗu tare da hydrogen a cikin walda, zai inganta ƙarfafawa na yankin da ke fama da zafi, wanda zai haifar da haɓakar ƙwayar sanyi da jinkirta tsage.

Lokacin da matsananciyar damuwa da ta rage a cikin walda ko matsananciyar nauyi mai ƙarfi a cikin aikin ɗaukar nauyi yana haɗuwa tare da aikin lalata na matsakaici, yana iya haifar da lalatawar fashewa, wanda shine abin da ake kira lalata damuwa.Matsalolin walda da taurin gindin ƙarfe wanda walda ke haifarwa sune mahimman abubuwan da ke haifar da lalatawar damuwa.

Sakamakon binciken ya nuna cewa babban tasirin nakasawa da raguwar damuwa akan kayan ƙarfe shine don canza ƙarfe daga lalata iri ɗaya zuwa lalata na gida, wato, lalatawar intergranular ko transgranular.Hakika, duka lalata fatattaka da intergranular lalata karafa faruwa a kafofin watsa labarai cewa suna da wasu halaye na karfe.

A gaban sauran danniya, shi ne daban-daban bisa ga abun da ke ciki, maida hankali da kuma zafin jiki na m matsakaici, kazalika da bambance-bambance a cikin abun da ke ciki, tsarin, surface jihar, danniya jihar, da dai sauransu na tushe karfe da waldi zone. , don lalata yanayin lalacewa na iya canzawa.

5. La'akari da cikakken tasirin PWHT

Maganin zafi bayan walda ba shi da cikakkiyar fa'ida.Gabaɗaya, maganin zafi bayan walda yana da amfani don kawar da damuwa na saura, kuma ana aiwatar da shi ne kawai lokacin da akwai ƙaƙƙarfan buƙatu don lalata damuwa.Duk da haka, tasirin taurin gwajin samfurin ya nuna cewa maganin zafi bayan walda ba shi da kyau ga taurin karfen da aka ajiye da kuma yankin da zafi ya shafa, kuma wani lokacin fashewar tsaka-tsakin na iya faruwa a cikin kewayon ƙwanƙwasa hatsi na zafin walda. yankin da abin ya shafa.

Bugu da ƙari kuma, PWHT yana dogara ne akan rage ƙarfin abu a babban zafin jiki don samun sauƙi na damuwa.Saboda haka, a lokacin PWHT, tsarin zai iya rasa rashin ƙarfi.Don tsarin da ke ɗaukar PWHT gabaɗaya ko wani ɓangare, weldment a babban zafin jiki dole ne a yi la'akari da shi kafin maganin zafi.iya aiki.

Sabili da haka, lokacin da ake la'akari da ko za a gudanar da maganin zafi bayan walda, amfani da rashin amfani na maganin zafi ya kamata a kwatanta shi sosai.Daga ra'ayi na aikin tsarin, akwai wani bangare don inganta aikin, da kuma sauran don rage yawan aiki.Ya kamata a yi hukunci mai ma'ana bisa cikakken la'akari da bangarorin biyu.

Lokacin aikawa: Juni-20-2023