Tushen makamashi na brazing na iya zama zafin amsa sinadarai ko makamashin zafi kai tsaye.Yana amfani da ƙarfe mai narkewa ƙasa da na kayan da za a yi walda a matsayin mai siyar.Bayan dumama, solder ɗin ya narke, kuma aikin capillary yana tura mai siyar zuwa cikin tazarar da ke tsakanin wuraren tuntuɓar haɗin gwiwa don jika saman ƙarfen da za a yi waldawa ta yadda yanayin ruwa da ƙaƙƙarfan lokaci suka rabu.Matsakaici tsakanin matakan don samar da haɗin gwiwa mai katsalandan.Don haka, brazing hanya ce mai ƙarfi da kuma hanyar walƙiya-lokaci.

1. Halaye da aikace-aikace na brazing

Brazing yana amfani da gawa mai narkewa ƙasa da na tushe a matsayin mai siyar.Lokacin da mai tsanani, solder narke kuma ya cika kuma ya kasance a cikin haɗin haɗin gwiwa ta hanyar wetting da aikin capillary, yayin da karfen tushe yake cikin yanayi mai ƙarfi, yana dogara ga mai siyar da ruwa da tushe mai ƙarfi tsakanin kayan yana haifar da haɗin gwiwa.Brazing yana da kadan tasiri a kan jiki da kuma sinadaran Properties na tushe karfe, m waldi danniya da kuma nakasawa, iya weld dissimilar karafa tare da manyan bambance-bambance a Properties, iya kammala mahara welds a lokaci guda, bayyanar da hadin gwiwa ne mai kyau da kuma tsabta, kayan aiki yana da sauƙi, kuma zuba jari na samar da ƙananan ƙananan.Koyaya, haɗin gwiwar brazed yana da ƙarancin ƙarfi da ƙarancin juriya na zafi.

Aikace-aikace: Carbide yankan kayan aikin, hakowa bits, kekuna Frames, zafi musayar, conduits da daban-daban kwantena, da dai sauransu.;a cikin kera na'urorin lantarki na lantarki, bututun lantarki da na'urorin injin lantarki, brazing ko da hanya ce kawai mai yuwuwar haɗi.

2.Ƙarfe mai ƙarfi da juyi

Brazing filler karfe ne mai filler wanda ke samar da kan brazing, kuma ingancin kan brazing ya dogara da ƙarfe mai cike da brazing zuwa ga girma.Ƙarfin filler ya kamata ya sami madaidaicin narkewa mai dacewa, mai kyau wettability da ikon caulking, za a iya yaduwa tare da karfe tushe, kuma ya kamata ya sami wasu kayan aikin injiniya da kayan jiki da na sinadarai don saduwa da bukatun aikin haɗin gwiwa.Dangane da nau'in narkewa daban-daban na ƙarfe mai filler brazing, brazing za a iya raba shi zuwa nau'i biyu: brazing mai laushi da tauri mai ƙarfi.

(1) Taushi mai laushi.Brazing tare da wurin narkewa da ke ƙasa da 450 ° C ana kiransa brazing mai laushi, kuma ƙarfe mai cike da brazing da aka saba amfani da shi shine tin gubar brazing, wanda ke da ingantaccen wettability da ƙarfin lantarki kuma ana amfani dashi sosai a cikin samfuran lantarki, kayan lantarki da sassa na mota.Ƙarfin haɗin gwiwar brazed gabaɗaya shine 60 ~ 140MPa.

(2) Tausayi.Brazing tare da wurin narkewa sama da 450 ° C ana kiransa brazing, kuma kayan aikin brazing na yau da kullun sune kayan brazing na tagulla da azurfa.Haɗin gwiwa tare da ƙarfe mai filler tushe na azurfa yana da ƙarfi mai ƙarfi, ƙarfin lantarki da juriya na lalata, wurin narkewar ƙarfen filler ba shi da ƙasa, kuma tsarin yana da kyau, amma farashin ƙarfen filler yana da yawa, kuma galibi ana amfani dashi don walda. sassan da buƙatu mafi girma.Ana amfani da brazing galibi don kayan aikin ƙarfe da jan ƙarfe tare da manyan runduna, da kayan aikin brazing.Ƙarfin haɗin gwiwa na 200 ~ 490MPa,

Lura: Alamar lamba na kayan tushe ya kamata ya zama mai tsabta sosai, don haka ya kamata a yi amfani da juzu'i.Matsayin jujjuyawar shine don cire oxide da ƙazantar mai a saman saman ƙarfe na tushe da ƙarfe mai filler, kare yanayin tuntuɓar ƙarfen filler da ƙarfe mai tushe daga oxidation, da haɓaka wettability da ruwa na capillary na filler. karfe.Matsayin narkewar juzu'in ya kamata ya zama ƙasa da na ƙarfe mai filler, kuma lalatawar juzu'i zuwa ƙarfen tushe da haɗin gwiwa yakamata ya zama ƙasa.Maganin brazing na yau da kullun shine rosin ko zinc chloride bayani, kuma ruwan brazing na kowa shine cakuda borax, boric acid da alkaline fluoride.

Dangane da hanyoyin zafi daban-daban ko hanyoyin dumama ana iya raba brazing zuwa:brazing harshen wuta, induction brazing, tanderu brazing, tsoma brazing, juriya brazing da sauransu.Saboda zafin jiki na dumama yana da ɗan ƙaramin ƙarfi yayin brazing, yana da ƙarancin tasiri akan aikin kayan aikin, kuma lalatawar walƙiya shima ƙanana ne.Koyaya, ƙarfin haɗin gwiwar brazed gabaɗaya yana ƙasa kaɗan, kuma juriya na zafi ba shi da kyau.

Hanyar dumama brazing:Kusan duk hanyoyin dumama ana iya amfani da su azaman tushen zafi na brazing, kuma bisa ga wannan brazing an rarraba su.

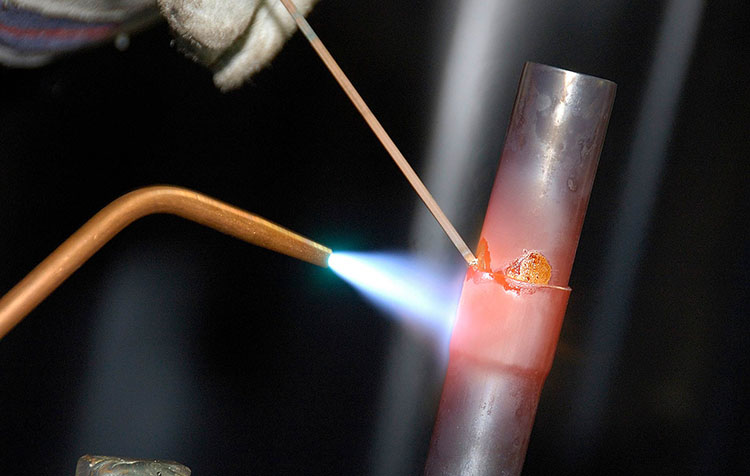

Harshen harshen wuta:dumama da harshen wuta, amfani da carbon karfe, bakin karfe, carbide, jefa baƙin ƙarfe, jan karfe da kuma tagulla gami, aluminum da aluminum gami brazing.

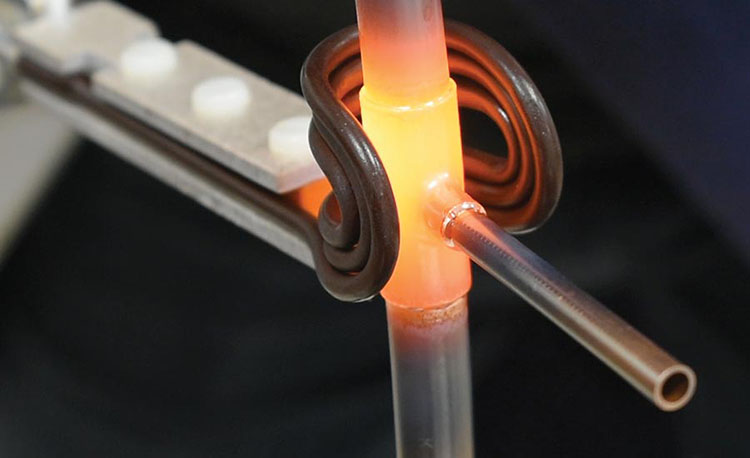

Induction brazing:Yin amfani da madaidaicin filayen maganadisu don haifar da halin yanzu a cikin ɓangaren juriya na dumama walda, don siffa mai ma'ana ta walda, musamman brazing na bututu.

Dip brazing:bangaren walda ne partially ko gaba daya immersed a cikin narkakkar gishiri cakuda ko solder narkewa, dogara ga zafin wadannan ruwa kafofin watsa labarai don cimma brazing tsari, wanda aka halin da sauri dumama, uniform zafin jiki, kananan nakasawa na walda part.

Tanderu brazing:Ana ɗora walda ta wuta ta juriya, wanda zai iya kare walda ta hanyar yayyafawa ko amfani da iskar gas mai rage ko rashin aiki.

Bugu da kari, akwai soldering baƙin ƙarfe brazing, juriya brazing, yada brazing, infrared brazing, dauki brazing, electron katako brazing, Laser brazing, da dai sauransu.

Ana iya amfani da brazing don walda karfen carbon, bakin karfe, superalloy, aluminum, jan karfe da sauran kayan karfe, kuma ana iya haɗa nau'ikan karafa, karafa da marasa ƙarfe.Ya dace da haɗin gwiwar walda tare da ƙananan kaya ko aiki a cikin zafin jiki, musamman dacewa da madaidaici, micro da hadaddun walda masu yawa.

Lokacin aikawa: Yuli-06-2023