Gabatarwa

Da yake jikin abin hawa shine mai ɗaukar wasu ɓangarori na abin hawa, fasahar kera shi kai tsaye yana ƙayyadad da ingancin ƙirar abin hawa gaba ɗaya.Welding wani muhimmin tsari ne na samarwa a cikin tsarin kera jikin mota.A halin yanzu, fasahohin walda da ake amfani da su don waldawar jikin mota galibi sun haɗa da walƙiya tabo mai juriya, walƙiyar MIG, walƙiyar MAG da walƙiyar Laser.

Fasaha walda Laser a matsayin ci-gaba na optoelectromechanical hadewar walda fasahar, idan aka kwatanta da na gargajiya mota jiki waldi fasahar, yana da abũbuwan amfãni daga high makamashi yawa, sauri waldi gudun, kananan waldi danniya da nakasawa, da kuma mai kyau sassauci.

Tsarin jikin mota yana da sarkakiya, kuma abubuwan da ke cikinsa galibi masu sirara ne da lankwasa.Waldawar jikin mota tana fuskantar wasu matsaloli, kamar canje-canje a kayan jiki, kauri daban-daban na sassan jiki, yanayin walda iri-iri da siffofin haɗin gwiwa.Bugu da kari, waldar jikin mota yana da bukatu masu yawa akan ingancin walda da ingancin walda.

Dangane da sigogin tsarin walda da suka dace, walƙiya na laser na iya tabbatar da ƙarfin ƙarfin gajiya da tasiri mai ƙarfi na mahimman abubuwan jikin motar, don tabbatar da ingancin walda da rayuwar sabis na jikin motar.Fasaha walda Laser na iya daidaitawa da nau'ikan haɗin gwiwa daban-daban, kauri daban-daban da nau'ikan nau'ikan walda na sassan jiki daban-daban, don saduwa da sassauƙan buƙatun masana'antar jiki ta atomatik.Saboda haka, Laser waldi fasahar ne mai muhimmanci fasaha wajen cimma high quality-ci gaban na mota masana'antu.

Laser walda fasahar na mota jiki

Laser zurfin shigar da fasahar walda na jikin mota

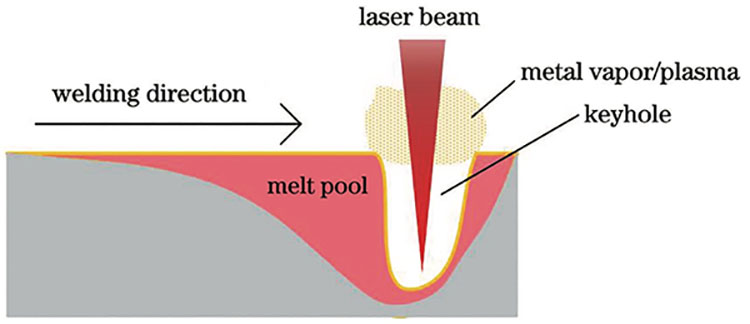

Ka'idar aikin walda mai zurfi na laser mai zurfi (Hoto 1) shine kamar haka: lokacin da yawan wutar lantarki ya kai wani matakin, saman kayan yana vaporizes, yana samar da maɓalli.Lokacin da ƙarfin tururi na ƙarfe a cikin rami ya kai ma'auni mai ƙarfi tare da matsa lamba mai tsayi da tashin hankali na ruwan da ke kewaye, ana iya haskaka laser zuwa kasan ramin ta hanyar maɓalli, kuma tare da motsi na katako na laser, ci gaba da ci gaba. weld aka kafa.A lokacin Laser zurfin shigar azzakari cikin farji waldi tsari, babu bukatar don ƙara ƙarin juyi ko filler, da workpiece ta nasu kayan za a iya welded tare.

FIG.1 Tsarin tsari na tsarin walƙiya mai zurfi na Laser

Weld ɗin da aka samu ta hanyar walƙiya mai zurfi mai zurfi na Laser gabaɗaya santsi ne kuma madaidaiciya, kuma nakasar ƙanƙanta ce, wacce ke haɓaka haɓaka daidaiton masana'anta na jikin mota.Ƙarfin ƙarfi mai ƙarfi na walda yana tabbatar da ingancin walda na jikin mota.Gudun walda yana da sauri, wanda ke da amfani don inganta haɓakar samar da walda.

A cikin aiwatar da waldawar jikin mota, yin amfani da tsarin walƙiya mai zurfi na Laser na iya rage adadin sassa, kyawu da kayan aikin walda, don haka rage nauyin jiki da farashin samarwa.Koyaya, tsarin walƙiya mai zurfi mai zurfi na Laser yana da ƙarancin haƙuri ga ratar taro na sassan welded, kuma ratar taron yana buƙatar sarrafa tsakanin 0.05 da 2 mm.Idan tazarar taron ta yi yawa, lahani na walda kamar pores zai faru.

A halin yanzu bincike ya nuna cewa weld da kyau surface forming, kasa na ciki lahani da kyau kwarai inji Properties za a iya samu ta hanyar inganta sigogi na Laser zurfin shigar waldi a cikin waldi na wannan abu na mota jiki.Kyawawan kayan aikin injin walda na iya biyan buƙatun abubuwan walda na jikin mota.Koyaya, a cikin waldawar jikin mota, nau'in nau'in nau'in ƙarfe na Laser zurfin fasahar walda wanda ke wakilta ta gami da aluminium da ƙarfe bai balaga ba.Ko da yake walda seams tare da kyakkyawan aiki za a iya samu ta ƙara mika mulki yadudduka, da tasiri inji na daban-daban mika mulki Layer kayan a kan IMC Layer da su mataki inji a kan walda microstructure ba a bayyana, da kuma kara bincike da ake bukata.

Mota jiki Laser waya cika walda tsarin

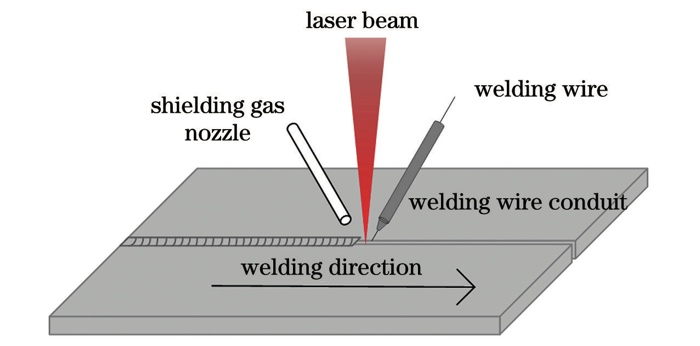

Ka'idar aikin walda waya na filler kamar haka: an kafa haɗin haɗin gwiwa ta hanyar cika takamaiman waya ta walda a cikin walda ko ciyar da wayar walda lokaci guda yayin aikin waldawar Laser.Wannan yayi daidai da shigar da kusan kayan walda na waya mai kama da juna a cikin tafkin walda yayin waldar zurfin shigar laser.An nuna zane-zane na tsarin waldawar waya ta Laser filler a hoto na 2.

FIG.2 Tsarin tsari na tsarin waldawar waya ta Laser

Idan aka kwatanta da Laser zurfin shigar waldi, Laser waya ciko waldi yana da biyu abũbuwan amfãni a auto jiki waldi: na farko, zai iya ƙwarai inganta haƙuri da taro rata tsakanin auto jiki sassa da za a welded, da kuma warware matsalar da cewa Laser zurfin shigar waldi waldi. yana buƙatar share tsagi da yawa;Na biyu, ana iya inganta rarraba nama na yankin walda ta hanyar amfani da wayoyi na walda tare da abun ciki daban-daban, sa'an nan kuma za'a iya daidaita aikin walda.

A cikin aiwatar da kera jikin mota, ana amfani da tsarin waldawar waya ta Laser don walda aluminium da sassan ƙarfe na jiki.Musamman a cikin tsarin walda na aluminum gami sassa na mota jiki, da surface tashin hankali na narkakkar pool ne kananan, wanda shi ne mai sauki kai ga rugujewar narkakkar pool, da Laser waya ciko walda tsari iya mafi alhẽri warware matsalar narkakkar pool rugujewa. ta hanyar narka wayar walda.

Laser brazing fasaha na mota jiki

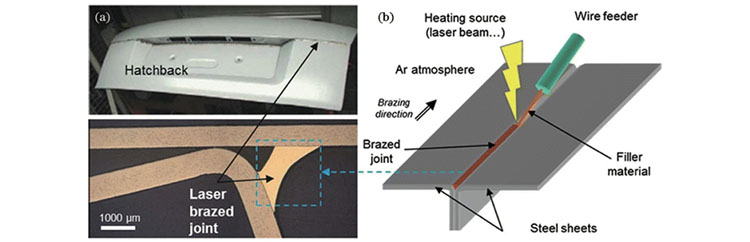

Ka'idar aikin brazing Laser shine kamar haka: ana amfani da Laser azaman tushen zafi, hasken wutar lantarki yana haskaka saman layin walda bayan an mayar da hankali, wayar walda ta narke, waya mai narkewa ta faɗo kuma an cika tsakanin sassa da za a welded, da metallurgical effects kamar narkewa da yadawa faruwa tsakanin filler karfe da workpiece, sabõda haka, workpiece yana da alaka.Ba kamar tsarin walƙiya na ciko waya ta Laser ba, aikin brazing na Laser yana narkar da waya kawai kuma baya narke aikin da za a yi wa walda.Laser brazing yana da kyakkyawan kwanciyar hankali na walda, amma ƙarfin ƙarfin walda yana da ƙasa.FIG.3 yana nuna aikace-aikacen tsarin brazing Laser a cikin waldawar murfi ta mota.

FIG.3 Aikace-aikace na Laser brazing a mota: (a) Laser waldi na raya kaho;(b) Zane-zane na Laser brazing

A cikin aiwatar da walƙiya jiki na mota, Laser brazing tsari ne yafi waldi sassa jiki tare da low hadin gwiwa ƙarfi bukatun, kamar waldi tsakanin saman murfin da gefen bango na jiki, da waldi tsakanin babba da ƙananan sassa na gangar jikin. cover, da dai sauransu, Volkswagen, Audi da sauran high-karshen model na saman murfin suna amfani da Laser brazing tsari.

Babban lahani a Laser brazing waldi kabu na mota jiki sun hada da gefen cizon, porosity, weld nakasawa, da dai sauransu A lahani za a iya kashe a fili ta daidaitawa sigogi da kuma yin amfani da Multi-mayar da hankali Laser brazing tsari.

Laser arc hada fasahar walda na jikin mota

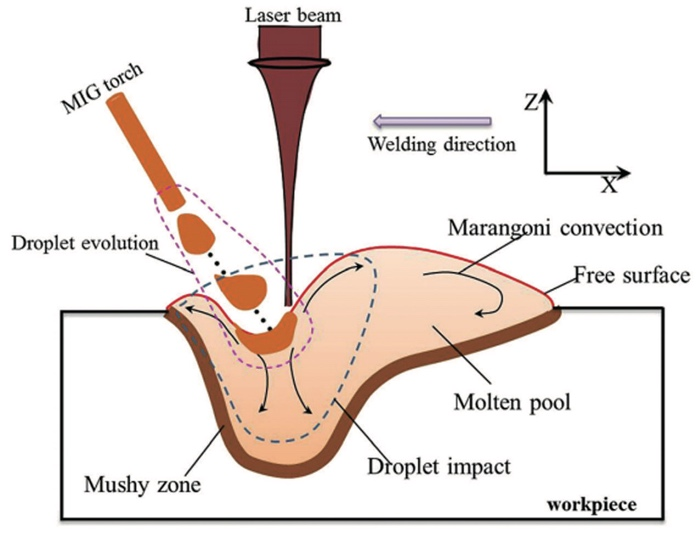

Ka'idar Laser-baka hada waldi tsari ne kamar haka: ta yin amfani da biyu zafi kafofin Laser da baka yi aiki a kan saman da workpiece da za a welded a lokaci guda, da workpiece ne narke da kuma karfafa samar da wani weld.Hoto na 4 yana nuna zane-zane na tsarin walda na Laser-arc.

FIG.4 Tsarin zane na Laser-arc composite waldi tsarin

Laser-arc composite waldi yana da abũbuwan amfãni na biyu Laser waldi da baka waldi: na farko, a karkashin mataki na biyu zafi kafofin, da waldi gudun da aka inganta, da zafi shigar da shi ne kananan, da walda nakasawa ne kananan, da kuma halaye na Laser waldi. ana kiyaye su;Na biyu, yana da mafi kyawun iya haɗawa da ƙarin juriya ga gibin taro;Na uku, da solidification kudi na narkakkar pool ne jinkirin, wanda shi ne m don kawar da lahani walda kamar pores da fasa, da kuma inganta tsari da kuma aiki na zafi shafi yankin.Na hudu, saboda tasirin arc, yana iya yin walda kayan aiki tare da babban haske da haɓakaccen zafi, kuma kewayon kayan aikin ya fi fadi.

A kan aiwatar da mota jiki masana'antu, da Laser-baka hada waldi tsari ne yafi weld aluminum gami aka gyara na jiki da aluminum-karfe dissimilar karafa, da kuma waldi da aka yi ga sassa da manyan taro gibba, kamar waldi na sassa na kofar mota, saboda ratar taron yana da amfani ga wasan gada na aikin walda na Laser-arc composite.Bugu da kari, Laser-MIG baka hada fasahar waldi kuma ana amfani da gefen saman katako matsayi na Audi jiki.

A cikin aiwatar da waldawar jikin mota, walƙiya-arc-arc ɗin haɗaɗɗun walda yana da fa'ida mafi girman juriyar juriya fiye da walƙiyar Laser guda ɗaya, amma matsayin dangi na Laser da arc, sigogin walda na laser, sigogin baka da sauran abubuwan yakamata a yi la'akari da su sosai.Halin zafi da canja wurin taro a cikin walƙiya-baka yana da rikitarwa, musamman ma tsarin tsarin makamashi da kauri na IMC da tsarin tsari a cikin waldawar kayan da ba ta dace ba har yanzu ba a sani ba, kuma ana buƙatar ƙarin bincike.

Sauran mota jiki Laser waldi tafiyar matakai

Laser zurfin shigar waldi, Laser waya cika waldi, Laser brazing da Laser-arc hada waldi da sauran waldi matakai sun kasance mafi balagagge ka'idar da kuma m aikace-aikace.Tare da haɓaka buƙatun masana'antar kera motoci don ingancin waldawar jiki da haɓaka buƙatun abubuwan waldawa iri ɗaya a masana'antar kera motoci masu nauyi, walƙiyar Laser tabo, walƙiyar Laser walƙiya, walƙiya mai walƙiya da yawa da walƙiyar jirgin Laser an biya hankali. ku.

Laser tabo walda tsari

Laser tabo waldi ne ci-gaba Laser waldi fasaha, wanda yana da abũbuwan amfãni daga cikin sauri waldi gudun da high waldi daidaici.Babban ka'idar walda tabo ta Laser ita ce mayar da hankali kan katakon Laser zuwa wani wuri a kan sashin da za a yi walda, ta yadda karfen da ke wurin ya narke nan take, ta hanyar daidaita yawan Laser don cimma walƙiyar thermal conduction waldi ko zurfin fusion waldi. , lokacin da katakon Laser ya daina aiki, ƙarfen ruwa ya sake kwarara, ya ƙarfafa don samar da haɗin gwiwa.

Akwai biyu main siffofin Laser tabo waldi: pulsed Laser tabo waldi da ci gaba da Laser tabo waldi.Pulsed Laser tabo walda Laser katako ganiya makamashi ne high, amma mataki lokaci ne takaice, kullum amfani ga magnesium gami, aluminum gami da sauran haske karafa waldi.A matsakaita ikon Laser katako a ci gaba da Laser tabo waldi ne high, da Laser mataki lokaci ne dogon, kuma shi ne yadu amfani a karfe waldi.

A cikin sharuddan mota jiki waldi, idan aka kwatanta da juriya tabo waldi, Laser tabo waldi yana da abũbuwan amfãni daga wadanda ba lamba, tabo waldi yanayin za a iya tsara da kansa, da dai sauransu, wanda zai iya saduwa da bukatun high quality waldi a karkashin daban-daban cinya gibba. kayan jikin mota.

Laser lilo walda tsari

Walda walda na Laser sabuwar fasahar walda ta Laser da aka gabatar a cikin 'yan shekarun nan, wanda ya damu sosai.Ka'idar wannan fasaha ita ce: ta hanyar haɗa rukunin galvanometer akan kan waldawar laser, ƙirar laser yana da sauri, tsari kuma a cikin ƙaramin yanki, don cimma tasirin tasirin laser yana motsawa gaba yayin motsawa.

Babban yanayin lilo a cikin tsarin walƙiya na Laser sun haɗa da lilo mai jujjuyawa, lilo mai tsayi, madauwari lilo da lilo mara iyaka.A Laser lilo waldi tsari yana da gagarumin abũbuwan amfãni a cikin waldi na mota jiki.Karkashin aikin lasar igiyar igiyar igiyar igiyar ruwa, yanayin tafkin narkakkar yana canzawa sosai.Sabili da haka, tsarin ba zai iya kawar da lahani da ba a haɗa shi kawai ba, cimma gyaran hatsi da kuma kawar da porosity a cikin walda na kayan jikin mota guda ɗaya.Bugu da kari, shi kuma iya inganta matsalolin kamar kasa hadawa na daban-daban kayan da matalauta inji Properties na welds a cikin walda na iri-iri kayan na mota jiki.

Multi-Laser katako walda tsari

A halin yanzu, Laser na gani fiber Laser za a iya raba zuwa mahara Laser katako ta splitter module shigar a cikin waldi shugaban.Multi-Laser beam waldi yana daidai da yin amfani da tushen zafi da yawa a cikin tsarin waldawa, ta hanyar daidaita rarraba makamashi na katako, nau'i-nau'i daban-daban na iya cimma ayyuka daban-daban, kamar: katako tare da mafi girman ƙarfin makamashi shine babban katako, alhakin zurfi. walƙiya shigar ciki;Ƙarƙashin ƙarancin makamashi na katako na iya tsaftacewa da preheat saman kayan, da kuma ƙara yawan shayar da makamashin Laser ta kayan.

Galvanized high-ƙarfin karfe abu ne yadu amfani a mota jiki.Fasahar walda ta laser da yawa na iya inganta haɓakar ƙawancen tururi na zinc tururi da ƙarfin hali na narkakken tafkin a cikin aikin walda na farantin karfe mai galvanized, inganta matsalar sputtering, da haɓaka ƙarfin ƙarfi na walda.

Tsarin walda jirgin Laser

Fasahar walda jirgin Laser sabuwar fasaha ce ta walƙiya, wacce ke da ƙarfin walƙiya kuma ana iya ƙirƙira ta kanta.Babban ka'idar waldawar jirgin Laser shine lokacin da katakon Laser ya faru akan madubin X da Y na madubin dubawa, ana sarrafa kusurwar madubin ta hanyar shirye-shirye masu zaman kansu don cimma karkatar da katakon Laser a kowane kusurwa.

Al'ada Laser waldi na mota jiki yafi dogara da synchronous motsi na Laser waldi shugaban kore ta waldi robot don cimma sakamako waldi.Koyaya, ingancin walda na jikin mota yana da matuƙar iyakancewa ta hanyar maimaita maimaita motsi na mutum-mutumin walda saboda yawan adadin walda da tsayin welds.Sabanin haka, waldar jirgin Laser kawai yana buƙatar daidaita kusurwar madubi don cimma walƙiya a cikin wani kewayo.Saboda haka, Laser jirgin waldi fasahar iya muhimmanci inganta waldi yadda ya dace da kuma yana da m aikace-aikace al'amurra.

Takaitawa da kuma bege

Tare da haɓaka masana'antar kera motoci, fasahar waldawar jiki a nan gaba za ta ci gaba da haɓaka ta fuskoki biyu: tsarin walda da fasaha mai hankali.

Jikin mota, musamman sabon jikin abin hawan makamashi, yana tasowa a cikin alkibla mara nauyi.Alloys masu nauyi, kayan hade da kayan da ba su da kama da juna za a fi amfani da su a cikin jikin mota, tsarin waldawar Laser na al'ada yana da wahala don saduwa da buƙatun walda, don haka babban inganci da ingantaccen tsarin walda zai zama yanayin ci gaba na gaba.

A cikin 'yan shekarun nan, kunno kai Laser waldi matakai, kamar Laser lilo waldi, Multi-Laser katako waldi, Laser jirgin waldi, da dai sauransu, sun kasance farkon ka'idar bincike da aiwatar bincike cikin sharuddan waldi ingancin da waldi yadda ya dace.A nan gaba, ya zama dole a hankali hada da kunno kai Laser waldi tsari tare da nauyi kayan da dissimilar kayan waldi al'amuran mota jiki, gudanar da zurfafa bincike a kan zane na Laser katako lilo yanayin, da mataki inji na Multi-Laser katako makamashi. da haɓaka ingancin waldan jirgin sama, da kuma bincika tsarin walƙiyar jikin mota mara nauyi.

Fasahar walda ta Laser na jikin mota tana haɗe sosai tare da fasaha mai hankali.A real-lokaci ji na Laser waldi jihar mota jiki da kuma feedback iko da tsari sigogi taka wani hukunci rawa a waldi quality.A halin yanzu fasaha waldi Laser fasaha mafi yawa amfani da pre-welding yanayin tsare-tsare da tracking da post-welding ingancin dubawa.A gida da waje, bincike kan gano lahani na walda da sarrafawar daidaita ma'aunin har yanzu yana kan matakin farko, kuma ba a yi amfani da fasahar sarrafa walda ta Laser ba a cikin masana'antar jikin mota.

Saboda haka, a cikin view of aikace-aikace halaye na Laser waldi fasahar a kan aiwatar da mota jiki waldi, wani fasaha ji tsarin ga Laser waldi tare da ci-gaba Multi-ma'auni kamar yadda core da wani high-gudun da high-madaidaici waldi robot kula da tsarin ya kamata ya zama. ɓullo da nan gaba don tabbatar da ainihin-lokaci da daidaito na duk fannoni na fasaha waldi Laser fasaha.Bude hanyar haɗin yanar gizo na "tsarin yanayin walƙiya kafin walda - siga mai daidaitawa na gano ingancin walda a kan layi bayan walda" don tabbatar da inganci da ingantaccen aiki.

Lokacin aikawa: Oktoba-16-2023