Akwai wasu matsaloli na asali a cikin nau'ikan walda na ƙarfe waɗanda ke hana haɓakar sa, kamar haɓakawa da aiwatar da yankin haɗakar ƙarfe mai kama da haka.Yawancin lalacewar tsarin walda na ƙarfe maras kama da shi yana faruwa a yankin haɗin gwiwa.Saboda daban-daban crystallization halaye na welds a cikin kowane sashe kusa da Fusion zone, Har ila yau, yana da sauƙi a samar da wani canji Layer tare da matalauta yi da canje-canje a cikin abun da ke ciki.

Bugu da kari, saboda dadewa a yanayin zafi mai yawa, layin yaduwa a wannan yanki zai fadada, wanda zai kara kara rashin daidaiton karfe.Haka kuma, a lokacin da dissimilar karafa suna welded ko bayan zafi magani ko high-zazzabi aiki bayan waldi, shi ne sau da yawa gano cewa carbon a kan low-gawa gefen "yi hijira" ta hanyar weld iyaka zuwa high-gawa weld, forming decarburization yadudduka a kan. bangarorin biyu na layin hadewa.Kuma carburization Layer, tushe karfe samar da wani decarburization Layer a kan low alloy gefen, da kuma carburization Layer siffofi a kan high gami waldi gefe.

Matsaloli da shingen amfani da haɓaka nau'ikan nau'ikan nau'ikan ƙarfe suna bayyana galibi ta fuskoki masu zuwa:

1. A dakin da zafin jiki, da inji Properties (kamar tensile, tasiri, lankwasawa, da dai sauransu) na welded hadin gwiwa yankin na dissimilar karafa ne gaba ɗaya mafi alhẽri daga na tushe karfe da za a welded.Duk da haka, a yanayin zafi mai zafi ko bayan aiki na dogon lokaci a yanayin zafi mai zafi, aikin haɗin gwiwar yana da ƙasa da na tushe.abu.

2. Akwai yankin miƙa mulki na martensite tsakanin austenite weld da pearlite tushe karfe.Wannan yanki yana da ƙananan tauri kuma babban Layer ne mai karyewa.Hakanan yanki ne mai rauni wanda ke haifar da lalacewa da lalacewa.Zai rage tsarin welded.amincin amfani.

3. Carbon ƙaura a lokacin bayan-weld zafi magani ko high-zazzabi aiki zai haifar da samuwar carburized yadudduka da decarburized yadudduka a bangarorin biyu na fusion line.An yi imani da cewa rage yawan carbon a cikin decarburized Layer zai haifar da manyan canje-canje (gaba ɗaya tabarbarewa) a cikin tsari da aikin yanki, yana sa wannan yanki ya zama mai saurin lalacewa a lokacin sabis.Sassan gazawar bututun mai zafi da yawa a cikin sabis ko a ƙarƙashin gwaji an tattara su a cikin Layer na decarburization.

4. Rashin gazawa yana da alaƙa da yanayi irin su lokaci, zafin jiki da matsananciyar damuwa.

5. Maganin zafi na bayan-weld ba zai iya kawar da ragowar rarraba damuwa a yankin haɗin gwiwa ba.

6. Rashin daidaituwa na sinadaran sinadaran.

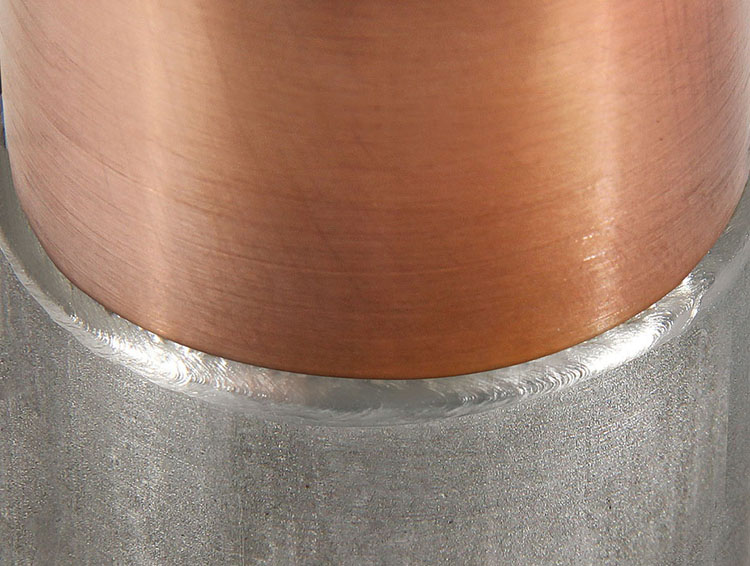

A lokacin da aka yi wa nau’in nau’in karafa iri-iri, tun da karfen da ke bangarorin biyu na walda da hadaddiyar giyar da ke cikin walda a fili sun bambanta, yayin aikin walda, karfen tushe da kayan walda za su narke su gauraya da juna.Daidaitawar haɗuwa za ta canza tare da canjin tsarin walda.Canje-canje, da haɗin kai kuma ya bambanta sosai a wurare daban-daban na haɗin gwiwar welded, wanda ke haifar da rashin daidaituwa na sinadarai na haɗin gwiwa.

7. Inhomogeneity na metallographic tsarin.

Sakamakon katsewar sinadarai na haɗin gwiwar welded, bayan fuskantar zagayowar yanayin walda, saituna daban-daban suna bayyana a kowane yanki na haɗin gwiwar welded, kuma tsarin ƙungiyoyi masu sarƙaƙƙiya sukan bayyana a wasu wurare.

8. Katsewar aiki.

Bambance-bambance a cikin abun da ke tattare da sinadarai da tsarin ƙarfe na welded gidajen abinci suna kawo abubuwa daban-daban na kayan aikin welded.Ƙarfin ƙarfi, taurin, filastik, tauri, kaddarorin tasiri, matsanancin zafin jiki, da kaddarorin dorewa na wurare daban-daban tare da haɗin gwiwar welded sun bambanta sosai.Wannan rashin daidaituwa mai mahimmanci yana sa wurare daban-daban na haɗin gwiwar welded su kasance daban-daban a ƙarƙashin yanayi iri ɗaya, tare da wurare masu rauni da kuma wuraren da aka ƙarfafa suna bayyana.Musamman a ƙarƙashin yanayin zafi mai yawa, nau'in haɗin gwiwar ƙarfe masu kama da juna suna cikin sabis yayin aikin sabis.Rashin gazawar farko yakan faru.

Halayen hanyoyin walda daban-daban lokacin walda ƙananan karafa

Yawancin hanyoyin walda za a iya amfani da su don walda nau'ikan karafa, amma lokacin zabar hanyoyin walda da tsara matakan tsari, ya kamata a yi la'akari da halayen nau'ikan nau'ikan karafa.Dangane da bukatu daban-daban na ginin karfen tushe da mahallin walda, walda fusion, walda matsi da sauran hanyoyin walda duk ana amfani da su wajen walda irin na ƙarfe, amma kowanne yana da nasa fa'ida da rashin amfani.

1. Walda

Hanyar walda wacce aka fi amfani da ita wajen waldawar karfe iri-iri ita ce waldar wutar lantarki, waldawar baka mai nutsewa, waldawar baka mai karewa, waldawar lantarki, waldar plasma, waldawar wutar lantarki, waldawar Laser, da sauransu. rabo ko sarrafa narke adadin daban-daban karfe tushe kayan, lantarki katako waldi, Laser waldi, plasma baka waldi da sauran hanyoyin da mafi girma zafi tushen makamashi yawa iya yawanci amfani.

Domin rage zurfin shigar ciki, ana iya ɗaukar matakan fasaha kamar baka kai tsaye, waya walda, tsiri lantarki, da ƙarin waya walda mara kuzari.Amma ko menene, in dai fusion waldi ne, wani sashi na karfen tushe koyaushe zai narke a cikin walda kuma ya haifar da dilution.Bugu da kari, za a samar da mahadi na intermetallic, eutectics, da sauransu.Domin rage irin wannan mummunar illa, dole ne a sarrafa da rage lokacin zama na karafa a cikin ruwa ko yanayin zafi mai ƙarfi.

Koyaya, duk da ci gaba da haɓakawa da haɓaka hanyoyin walda da matakan aiwatarwa, har yanzu yana da wahala a magance duk matsalolin lokacin walda ƙananan ƙarfe, saboda akwai nau'ikan ƙarfe da yawa, buƙatun aiki daban-daban, da nau'ikan haɗin gwiwa daban-daban.A lokuta da yawa, wajibi ne don matsa lamba walda ko wasu hanyoyin walda ana amfani da su don magance matsalolin walda na ƙayyadaddun haɗin gwiwar ƙarfe na musamman.

2. Matsi waldi

Yawancin hanyoyin walda matsi kawai suna dumama karfen da za'a yi masa walda zuwa wata robobi ko ma ba sa dumama shi, sai dai a yi amfani da wani matsi a matsayin siffa ta asali.Idan aka kwatanta da waldawar fusion, waldin matsa lamba yana da wasu fa'idodi lokacin walda nau'ikan haɗin gwiwa na ƙarfe.Muddin tsarin haɗin gwiwa yana ba da izini kuma ingancin walda zai iya biyan buƙatun, walƙiya mai matsa lamba sau da yawa shine mafi kyawun zaɓi.

A lokacin waldawar matsin lamba, saman mu'amala na nau'ikan karafa iri ɗaya na iya narke ko a'a.Sai dai saboda tasirin matsi, ko da akwai narkakkar karfe a saman, za a fitar da shi a fitar da shi (kamar walda mai walƙiya da walƙiya).Kawai a cikin 'yan lokuta Da zarar narkakkar karfe ya kasance bayan waldawar matsin lamba (kamar walda tabo).

Tunda waldawar matsa lamba ba ta zafi ko zafin zafin zafi ba ya yi ƙasa, zai iya rage ko guje wa illar da ke tattare da zagayowar thermal a kan kaddarorin ƙarfe na ƙarfen tushe kuma ya hana haɓakar abubuwan haɗin gwiwar tsaka-tsaki.Wasu nau'ikan walda na matsi na iya matse mahaɗin tsaka-tsakin da aka ƙirƙira daga haɗin gwiwa.Bugu da ƙari, babu matsala na canje-canje a cikin kaddarorin ƙarfe na weld da ke haifar da dilution yayin waldawar matsa lamba.

Duk da haka, yawancin hanyoyin walda matsi suna da wasu buƙatu don nau'in haɗin gwiwa.Misali, walƙiya tabo, walƙiyar kabu, da walƙiya na ultrasonic dole ne su yi amfani da haɗin gwiwar cinya;a lokacin gogayya waldi, aƙalla daya workpiece dole ne a yi jujjuya jiki giciye-sashe;waldawar fashewa yana aiki ne kawai ga Haɗin yanki mafi girma, da sauransu. Har yanzu kayan walda ɗin ba su shahara ba tukuna.Waɗannan babu shakka suna iyakance iyakar aikace-aikacen walda matsi.

3. Sauran hanyoyin

Baya ga walda da walda mai matsa lamba, akwai hanyoyi da yawa da za a iya amfani da su wajen walda nau'ikan karafa.Misali, brazing wata hanya ce ta walda nau'ikan karafa masu kama da juna tsakanin karfen filler da karfen tushe, amma abin da aka tattauna anan shine hanya ta musamman ta brazing.

Akwai wata hanya da ake kira fusion walding-brazing, wato, ƙananan ƙarfen tushe mai ƙarancin narkewa na haɗin haɗin ƙarfe mai kama da fusion-welded, kuma babban gefen ƙarfe na tushe mai narkewa yana da ƙarfi.Kuma galibi ana amfani da ƙarfe ɗaya kamar ƙaramin kayan tushe mai narkewa azaman mai siyar.Don haka, tsarin waldawa tsakanin karfen filler na brazing da ƙananan ƙarfe tushe na narkewa iri ɗaya ne, kuma babu matsaloli na musamman.

Tsarin brazing yana tsakanin karfen filler da babban ƙarfe tushe mai narkewa.Ƙarfe na tushe baya narke ko ƙirƙira, wanda zai iya guje wa matsaloli masu yawa na weldability, amma ana buƙatar karfen filler don samun damar jika karfen tushe da kyau.

Wata hanya kuma ana kiranta eutectic brazing ko eutectic diffusion brazing.Wannan shi ne don ɗora fuskar tuntuɓar nau'ikan karafa da ba su da kamanni zuwa wani yanayin zafi, ta yadda karafa biyu su zama eutectic mai ƙarancin narkewa a farfajiyar lamba.The low-narke-point eutectic ruwa ne a wannan zafin jiki, da gaske zama irin solder ba tare da bukatar waje solder.Hanyar brazing.

Tabbas, wannan yana buƙatar ƙirƙirar eutectic mai ƙarancin narkewa tsakanin ƙarfe biyu.A lokacin rarrabuwar ruwa na metimilar metals, kayan kwanon rufi na tsaka-tsakin abu yana mai da yawa a ƙarƙashin matsanancin narkewa tare da ƙarfe da za a welded.Ruwan bakin ciki na ruwa da aka kafa a wannan lokacin, bayan wani lokaci na tsarin adana zafi, yana sa kayan tsaka-tsakin narke.Lokacin da aka watsar da duk matsakaicin kayan Layer a cikin kayan tushe kuma an daidaita su, ana iya samar da haɗin gwiwa na ƙarfe ba tare da tsaka-tsaki ba.

Irin wannan hanyar za ta samar da ƙananan ƙarfe na ruwa yayin aikin walda.Saboda haka, shi ne kuma ake kira ruwa lokaci mika mulki waldi.Siffar su ta gama gari ita ce, babu tsarin simintin gyare-gyare a cikin haɗin gwiwa.

Abubuwan da ya kamata a lura lokacin walda nau'ikan karafa iri-iri

1. Yi la'akari da abubuwan da ke cikin jiki, kayan aikin injiniya da sinadaran sinadaran walda

(1) Daga hangen nesa daidai ƙarfin, zaɓi sandunan walda waɗanda ke saduwa da kayan aikin injiniya na ƙarfe na tushe, ko haɗa haɗin haɗin ginin ƙarfe tare da sandunan walda tare da ƙarfin da ba daidai ba kuma mai kyau weldability, amma la'akari da tsarin tsari na weld saduwa da daidai ƙarfi.Ƙarfi da sauran buƙatun taurin kai.

(2) Sanya kayan haɗin gwal ɗin sa daidai da ko kusa da kayan tushe.

(3) Lokacin da tushe karfe ya ƙunshi manyan matakan C, S, da P masu illa masu cutarwa, ya kamata a zaɓi sandunan walda tare da mafi kyawun juriya da juriya na porosity.Ana ba da shawarar yin amfani da electrode na calcium titanium oxide.Idan har yanzu ba za a iya warware shi ba, ana iya amfani da sandar walda mai ƙarancin hydrogen sodium.

2. Yi la'akari da yanayin aiki da aikin walda

(1) A ƙarƙashin yanayin ɗaukar nauyi mai ƙarfi da nauyin tasiri, ban da tabbatar da ƙarfi, akwai manyan buƙatu don tasirin tasiri da haɓakawa.Low nau'in hydrogen, nau'in titanium na calcium da nau'in lantarki irin na baƙin ƙarfe oxide yakamata a zaɓi lokaci ɗaya.

(2) Idan a lamba tare da m kafofin watsa labarai, dace bakin karfe waldi sanduna dole ne a zaba bisa nau'in, maida hankali, aiki zafin jiki na kafofin watsa labarai, da kuma ko general tufafi ko intergranular lalata.

(3) Lokacin aiki a ƙarƙashin yanayin lalacewa, ya kamata a bambanta ko na al'ada ne ko tasirin tasiri, da kuma ko yana sawa a yanayin zafi na al'ada ko yanayin zafi.

(4) Lokacin aiki a ƙarƙashin yanayin yanayin zafi ba, yakamata a zaɓi sandunan walda masu dacewa waɗanda ke tabbatar da ƙarancin ƙarancin zafin jiki ko manyan kayan aikin injin.

3. Yi la'akari da rikitaccen nau'i na nau'i na nau'i na nau'i na walda, da taurin kai, shirye-shiryen fashewar walda da matsayi na walda.

(1) Don walda tare da hadaddun sifofi ko manyan kauri, raguwar damuwa na ƙarfe na walda yayin sanyaya yana da girma kuma fashe yana yiwuwa ya faru.Dole ne a zaɓi sandunan walda mai ƙarfi mai ƙarfi, kamar sandunan walda mai ƙarancin hydrogen, sandunan walda mai ƙarfi ko kuma sandunan walda na oxide na ƙarfe.

(2) Don abubuwan walda waɗanda ba za a iya jujjuya su ba saboda sharuɗɗa, dole ne a zaɓi sandunan walda waɗanda za a iya walda su a kowane matsayi.

(3) Don sassan walda waɗanda ke da wahalar tsaftacewa, yi amfani da sandunan walda na acidic waɗanda ke da ƙarfi sosai kuma ba su da hankali ga sikelin da mai don guje wa lahani kamar pores.

4. Yi la'akari da kayan aikin gidan walda

A wuraren da babu na'urar walda DC, bai dace a yi amfani da sandunan walda tare da ƙarancin wutar lantarki na DC ba.Maimakon haka, yakamata a yi amfani da sandunan walda tare da wutar lantarki ta AC da DC.Wasu karafa (kamar karfe mai jure zafi na pearlitic) suna buƙatar kawar da damuwa na zafi bayan walda, amma ba za a iya magance zafi ba saboda yanayin kayan aiki (ko gazawar tsari).Ya kamata a yi amfani da sandunan walda da kayan ƙarfe marasa tushe (kamar austenitic bakin karfe) maimakon, kuma maganin zafi bayan walda ba lallai bane.

5. Yi la'akari da inganta hanyoyin walda da kare lafiyar ma'aikata

Inda duka na'urorin lantarki na acidic da alkaline zasu iya biyan buƙatun, yakamata a yi amfani da na'urorin lantarki gwargwadon yiwuwa.

6. Yi la'akari da yawan yawan aiki da ma'anar tattalin arziki

A cikin yanayin wasan kwaikwayon iri ɗaya, yakamata mu yi ƙoƙari mu yi amfani da sandunan walda na acidic mai ƙarancin farashi maimakon sandunan walda na alkaline.Daga cikin sandunan walda na acidic, nau'in titanium da nau'in titanium-calcium sune mafi tsada.Dangane da halin da ake ciki na albarkatun ma'adinai na kasata, ya kamata a inganta ƙarfin ƙarfe na titanium.sandar walda mai rufi.

Lokacin aikawa: Oktoba-27-2023